Mitsubishi Heavy Industries, Ltd. (MHI) has concluded a license agreement with Kellogg Brown & Root, Ltd. (KBR, Ltd.), an operating company of the first-tier American engineering firm KBR, Inc., to provide CO2 capture technology for a low carbon hydrogen production plant being established in Cheshire in northwest England. The project, Hydrogen Production Plant 2 (HPP2), will be constructed at the Stanlow Manufacturing Complex, which hosts one of the UK's leading refineries. The project owner is EET Hydrogen, the leading player in low carbon hydrogen production projects in the UK. KBR, Ltd. will provide hydrogen production process technology and the front-end engineering design ("FEED").

Under the agreement, MHI will license its "Advanced KM CDR Process™", CO2 capture technology developed in collaboration with the Kansai Electric Power Co., Inc., and also provide the process design package (PDP) for the new post combustion CO2 capture plant. HPP2 will have an annual hydrogen production capacity of nearly 230,000 tons, which is expected to be the UK's largest-scale low carbon hydrogen plants when it begins operation. HPP2 is a key pillar of the HyNet carbon capture, utilization and storage (CCUS) cluster. The captured CO2 will be permanently sequestered into depleted gas fields under the sea in Liverpool Bay.

The UK Government's Department for Energy Security and Net Zero (DESNZ) has selected two initial clusters - HyNet (where EET Hydrogen is leading the critical hydrogen production projects) and East Coast. HPP2 augments the Hydrogen Production Plant 1 (HPP1) scheduled for construction as part of the large-scale low carbon hydrogen plant infrastructure planned by EET Hydrogen in the HyNet cluster.

MHI Group has formally declared its intent to achieve carbon neutrality by 2040, and the Company is now working strategically to decarbonize both the energy demand and supply sides. A core element of the Company's "Energy Transition," which targets decarbonization on the energy supply side, is the development of a CO2 solutions ecosystem integrating diverse sources of carbon emissions with modes for carbon storage and utilization. Going forward, MHI Group will continue to proactively promote its CCUS business worldwide, applying its proprietary CO2 capture technologies, contributing as a solutions provider to reducing greenhouse gas emissions on a global scale, and developing further solutions that contribute to environmental protection.

About MHI Group's CO2 capture technologies

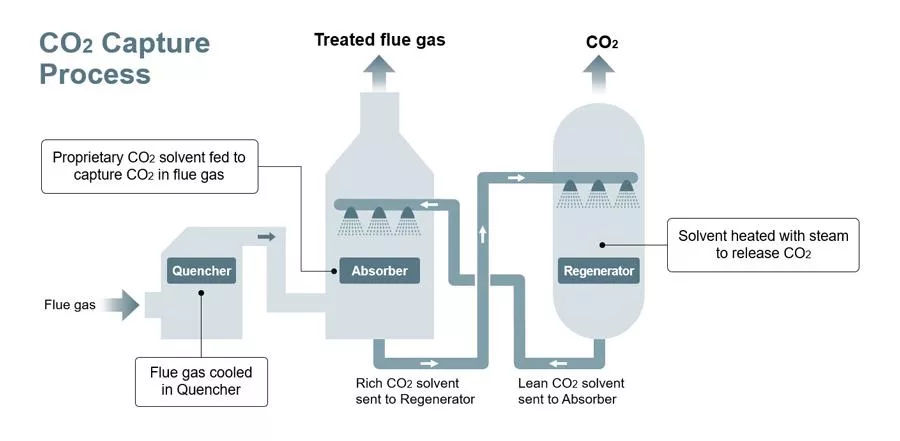

MHI Group has been developing the KM CDR Process™ (Kansai Mitsubishi Carbon Dioxide Recovery Process) and the Advanced KM CDR Process™ in collaboration with the Kansai Electric Power Co., Inc. since 1990. As of March 2024, the Company has delivered 16 plants adopting the KM CDR Process™, and two more are currently under construction. The Advanced KM CDR Process™ adopts the KS-21™ solvent, which incorporates technological improvements over the amine-based KS-1™ adopted at all 16 of the commercial CO2 capture plants delivered to date. The advanced version offers superior regeneration efficiency and lower deterioration than the KS-1™, and it has been verified to provide excellent energy saving performance, reduce operation costs, and result in low amine emissions.

For further information on MHI Group's CO2 capture plants: www.mhi.com/products/engineering/co2plants.html

About MHI Group

Mitsubishi Heavy Industries (MHI) Group is one of the world’s leading industrial groups, spanning energy, smart infrastructure, industrial machinery, aerospace and defense. MHI Group combines cutting-edge technology with deep experience to deliver innovative, integrated solutions that help to realize a carbon neutral world, improve the quality of life and ensure a safer world. For more information, please visit www.mhi.com or follow our insights and stories on spectra.mhi.com.

Copyright 2024 JCN Newswire. All rights reserved. www.jcnnewswire.com